Creating and reading ring gear patterns (also known as gear tooth contact patterns) is a critical step in setting up a differential properly. This ensures the pinion gear and ring gear mesh correctly, which directly affects performance, noise, and longevity.

How to Create a Ring Gear Pattern?

1. Apply Gear Marking Compound

- Use a gear marking compound (yellow, white, or blue compound) and apply it to 3–4 teeth on both the drive and coast sides of the ring gear.

- Spin the ring gear while applying light pressure to the pinion gear to create a realistic load. You can do this by rotating the pinion with resistance on the ring gear (e.g., using a pry bar on the yoke).

2. Rotate the Gears

- Rotate the ring gear through the pinion gear in both directions (drive and coast).

- Perform multiple rotations to ensure the marking compound leaves a clear contact pattern.

How to Read the Ring Gear Pattern?

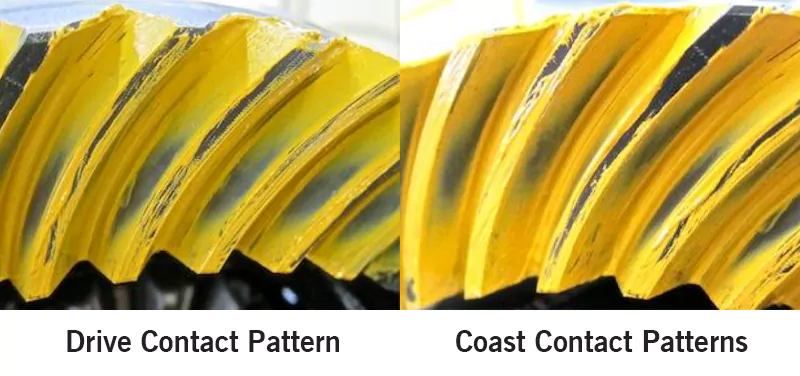

Desirable Contact Pattern

The contact pattern on the drive side (convex) of the tooth is centered. The contact

pattern on the coast side (concave) of the tooth is centered. Notice in this

photograph that both the drive and coast patterns are of equal length and equally

centered.

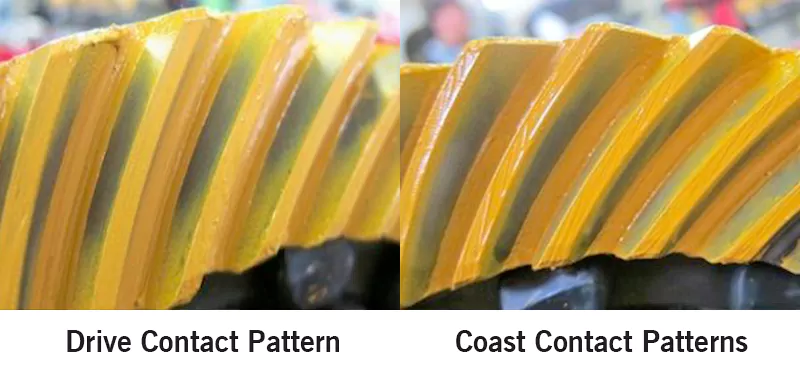

Toe-Heel Contact Pattern

The contact pattern on the drive side (convex) of the

tooth is mostly towards the toe.

The contact pattern on the coast side (concave) of the

tooth is mostly towards the heel

Correction: Move the pinion gear closer to the ring gear.

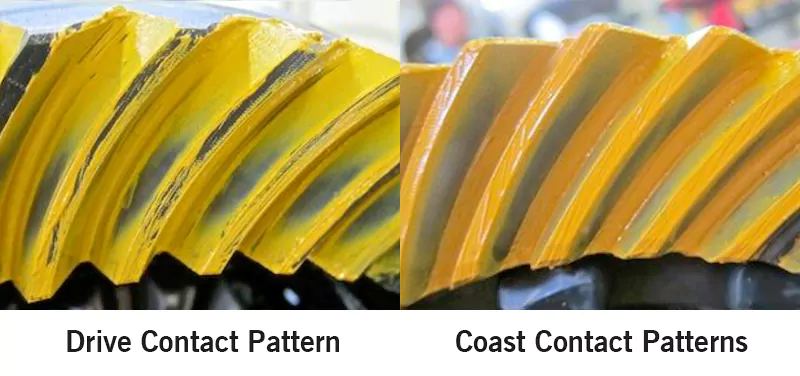

Heel-Toe Contact Pattern

The contact pattern on the drive side (convex) of the

tooth is mostly towards the heel.

The contact pattern on the coast side (concave) of the

tooth is mostly towards the toe.

Correction: Move the pinion gear away from the ring gear.

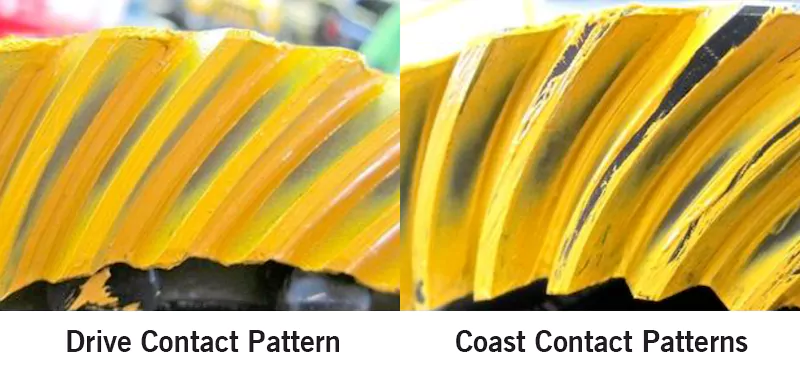

Toe-Toe Contact Pattern

The contact pattern on the drive side (convex) of the

tooth is mostly towards the toe.

The contact pattern on the coast side (concave) of the

tooth is mostly towards the toe.

Correction: Increase the ring gear backlash.

Heel-Heel Contact Pattern

The contact pattern on the drive side (convex) of the

tooth is mostly towards the heel.

The contact pattern on the coast side (concave) of the

tooth is mostly towards the heel.

Correction: Decrease the ring gear backlash.

Conclusion

Proper ring and pinion setup isn’t just about eliminating noise—it’s about ensuring optimal gear mesh, minimizing wear, and maintaining load-bearing efficiency under both drive and coast conditions. Precision here translates directly into durability, drivetrain efficiency, and overall vehicle performance. In short: measure twice, check your pattern, and adjust with purpose.