If you’re getting into off-road upgrades, differential tuning, or aftermarket gear sets, you may have come across terms like two-cut, five-cut, face-hobbed, and face-milled ring and pinions. These aren’t just buzzwords — they refer to the actual gear cutting process used to manufacture your ring and pinion gears. Understanding the difference can help you choose the right product for your application.

What Do “Two-Cut” and “Five-Cut” Actually Mean?

These terms describe how the tooth profile of the ring and pinion gears are formed during manufacturing.

- Five-Cut (also known as Face Milled) gears are cut in five separate passes, resulting in a more traditional gear profile.

- Two-Cut (also known as Face Hobbed) gears are produced in two high-efficiency passes using more advanced CNC hobbing machines.

While both methods can create strong, high-quality gears, they result in different tooth geometries, which affect how the gears mesh, wear, and perform under load.

Key Tooth Shape Differences

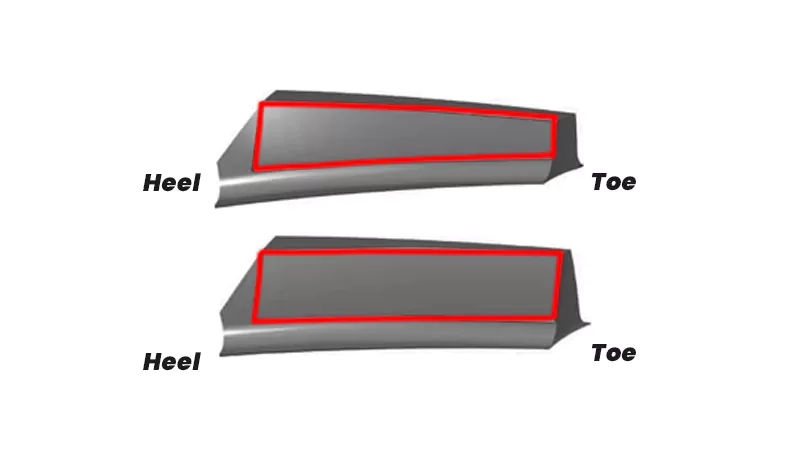

Five-Cut / Face-Milled Gears:

- Heel-to-Toe tooth depth varies.

- The heel (outer edge) is typically taller than the toe (inner edge).

- This provides better performance under load, especially in high-torque, off-road use.

- Gear mesh is more forgiving and pattern tuning is easier during setup.

Two-Cut / Face-Hobbed Gears:

- Constant depth from heel to toe — also called “uniform-height teeth.

- Gears tend to show a natural diagonal pattern bias during marking tests.

- Allows for faster production — widely used by OEM manufacturers due to speed and consistency.

- Requires more precision during installation to set proper contact pattern.

How to Identify?

You can visually tell the difference by examining the ring gear teeth:

- Five-Cut Gear: You’ll notice varying tooth height, with the heel visibly taller.

- Two-Cut Gear: The teeth appear uniform in height from heel to toe.

A gear marking compound test will also show the difference: two-cut gears often show a diagonal or slanted contact pattern, while five-cut gears produce a more centered and balanced contact area.

Get the Right Gear Set for Your Build

Whether you’re upgrading for trail use, towing, or performance off-roading, choosing the right ring and pinion set is critical. XJXPARTS is your factory-direct supplier, specializing in differential locks, crown wheel gear sets.

Contact our engineering team today for tailored advice and product support.