In automotive engineering, few components are as vital—and as often misunderstood—as the pinion. You might have heard terms such as crown wheel and pinion, ring and pinion set, or differential gears when talking about a vehicle’s drivetrain system. Yet, many people are unsure how these parts actually work together. Understanding what a pinion is and how it interacts with the crown wheel reveals the key to smooth power delivery, reliable performance, and long-lasting durability on the road.

What Is a Pinion?

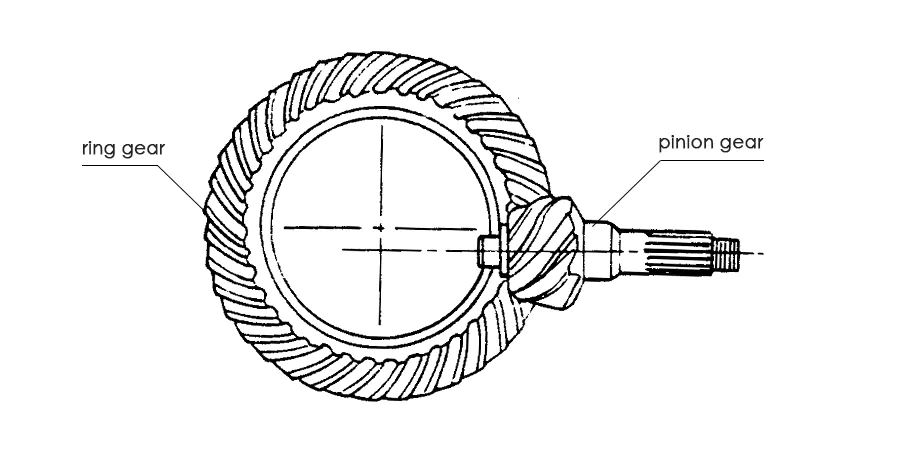

A pinion is the smaller of two gears in a meshing pair. It engages with a larger gear—commonly called a crown wheel or ring gear—to transmit torque and rotational motion. In most automotive contexts, the pinion is connected to the driveshaft and acts as the driving gear, transferring power to the differential and axle shafts.

Simply put, when people ask “what is a pinion?”, the answer is that it’s the driver gear responsible for translating engine or transmission output into usable wheel motion. Its precision and alignment directly affect how efficiently power reaches the ground.

How the Crown Wheel and Pinion Work Together

The crown wheel and pinion form the heart of a vehicle’s differential system. Together, they convert the rotational motion from the driveshaft into the torque that turns the wheels. This pair not only changes the direction of power flow—typically by 90 degrees—but also adjusts the gear ratio to control speed and torque.

When the pinion gear rotates, its teeth engage the larger crown wheel, multiplying torque while reducing speed. This process allows vehicles to accelerate smoothly from a standstill and maintain traction under varying road conditions.

Key Functions:

- Torque Conversion: The small pinion transfers power to the larger crown wheel, amplifying torque for wheel movement.

- Speed Regulation: The gear ratio between the crown wheel and pinion determines how quickly the wheels rotate relative to engine speed.

- Direction Change: In a differential, the crown wheel and pinion redirect power flow from the driveshaft (longitudinal) to the axles (lateral).

Types of Pinions and Their Applications

1. Spur Pinion

With straight-cut teeth, spur pinions are simple, efficient, and cost-effective. However, they generate more noise compared to helical types, making them more suitable for industrial or low-speed applications.

2. Helical Pinion

Helical pinions feature angled teeth for smoother, quieter operation. They are widely used in crown wheel and pinion differentials, where reduced noise and vibration are essential for driver comfort and drivetrain longevity.

3. Bevel Pinion

Bevel pinions have conical shapes and are designed to work with bevel gears—such as the crown wheel—to transmit power at an angle. These are standard in automotive differentials, enabling the 90-degree change in power direction from driveshaft to axle.

4. Hypoid Pinion

Most modern vehicles use a hypoid crown wheel and pinion set. The pinion sits slightly below the centerline of the crown wheel, reducing noise and increasing torque capacity. This design also allows for lower driveshaft placement, improving vehicle stability.

The Role of the Crown Wheel and Pinion in the Differential

In a typical rear-wheel-drive vehicle, the pinion gear connects to the driveshaft via the pinion yoke. When the driveshaft spins, it drives the pinion, which in turn rotates the crown wheel. The crown wheel is bolted to the differential carrier, which distributes torque to the axle shafts and wheels.

This setup provides two essential benefits:

- Different Wheel Speeds During Turns: The differential allows each wheel to rotate at different speeds, reducing tire wear and improving control.

- Torque Transfer Efficiency: The crown wheel and pinion gears ensure efficient energy transfer while withstanding high loads.

Common Applications

- Passenger vehicles (rear and four-wheel-drive)

- Commercial trucks

- Off-road and performance vehicles

- Agricultural and construction machinery

Selecting the Right Crown Wheel and Pinion Ratio

Choosing the correct crown wheel and pinion ratio can dramatically affect a vehicle’s performance. The ratio is determined by dividing the number of teeth on the crown wheel by the number of teeth on the pinion.

- Higher Ratio (e.g., 4.88:1): More torque, better acceleration, but reduced top speed.

- Lower Ratio (e.g., 3.23:1): Higher speed, better fuel economy, but less low-end torque.

For off-road or towing applications, a higher ratio offers better traction. In contrast, performance or racing vehicles often favor lower ratios for speed and efficiency.

Materials and Manufacturing of Pinions

Both pinions and crown wheels are typically made from high-strength steel alloys such as 8620 or 4320 steel. The manufacturing process involves precision forging, CNC machining, and heat treatment (carburizing or induction hardening) to enhance surface durability.

The quality of the crown wheel and pinion gear set directly influences:

- Noise and vibration levels

- Power transmission efficiency

- Service life of differential components

High-performance manufacturers like XJX Auto Parts apply advanced grinding and lapping techniques to achieve precise tooth contact and minimal backlash. Each gear set is produced under strict quality control standards to deliver consistent performance across different vehicle models.

If you’re looking for durable and accurately machined crown wheel and pinion gears for your business or project, feel free to contact XJX Auto Parts to discuss specifications and model compatibility.

Common Issues and Maintenance Tips

Because crown wheel and pinion gears operate under high load and speed, they require proper care and setup. Here are some essential maintenance considerations:

1. Lubrication

Use high-quality gear oil with appropriate viscosity to prevent wear and overheating. Insufficient lubrication can cause scoring, pitting, and gear failure.

2. Correct Setup

Improper pinion depth or backlash adjustment can lead to uneven contact patterns and noise. Always ensure professional setup during installation or ratio changes.

3. Inspection

Check for wear patterns, chipped teeth, or oil leaks. Unusual humming or whining sounds during acceleration often indicate crown wheel and pinion misalignment.

4. Break-in Process

After installing a new set, run the vehicle under moderate load for several cycles to allow the gears to seat properly. This extends the life of both the crown wheel and pinion.

How to Identify a Worn Pinion or Crown Wheel

- Whining Noise During Drive or Deceleration – Often caused by worn or misaligned pinion bearings.

- Vibration or Clunking – Could indicate backlash issues or tooth damage.

- Metallic Debris in Oil – Signals severe gear wear or spalling.

Summary: Why the Crown Wheel and Pinion Matter

Understanding what a pinion is goes beyond basic gear terminology—it’s about grasping how motion and power are transferred within your vehicle. The crown wheel and pinion system ensures the right balance between torque and speed, delivering stable, efficient performance across diverse driving conditions.

From daily commuting to high-performance racing, a properly designed and maintained crown wheel and pinion set can dramatically enhance vehicle reliability and driving experience.

If you are looking for high-quality aftermarket or OEM replacement crown wheel and pinion gears, contact us now!