The differential is one of the most critical yet often overlooked components of any vehicle’s drivetrain. Whether you are driving a compact car, a high-performance sports car, or a heavy-duty semi-truck, the differential plays a vital role in how your vehicle handles, accelerates, and maintains traction. Although many drivers have heard of it, few fully understand what a differential does, why it is necessary, and how different designs can drastically affect vehicle performance.

In this article, we will take a deep dive into the world of differentials. We will explain what a differential is, how it works, the various types of differentials used in modern vehicles, and the importance of regular maintenance. By the end, you will have a complete understanding of this essential mechanical device and how it impacts both everyday driving and specialized applications.

What Is a Differential?

At its core, a differential is a mechanical device located between the drive wheels of a vehicle. Its primary purpose is to allow those wheels to rotate at different speeds while still receiving power from the engine. This function might sound unnecessary at first, but it is absolutely essential for proper handling and safety.

When a vehicle makes a turn, the outer wheel must travel a greater distance than the inner wheel. If both wheels were forced to rotate at exactly the same speed, one of them would slip, skip, or drag across the road surface. This would not only create poor handling but also increase tire wear and put enormous stress on the drivetrain. The differential solves this problem by splitting the engine’s torque and allowing each wheel to rotate independently as needed.

How Does a Differential Work?

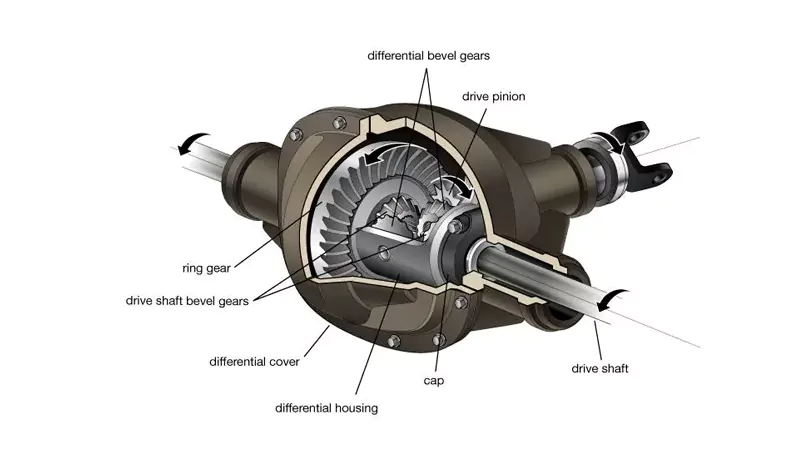

Inside a typical differential is a series of gears, including a ring gear, pinion gear, spider gears, and side gears. The driveshaft transfers rotational force into the pinion gear, which in turn rotates the ring gear connected to the differential case. From here, the spider gears distribute torque to the side gears and axle shafts, allowing the wheels to spin at different speeds during cornering.

This gear arrangement makes the differential one of the most ingenious and practical mechanical systems in automotive engineering. Without it, everyday driving would be inefficient, uncomfortable, and in many cases unsafe.

The Different Types of Differentials

Not all differentials are created equal. Over the years, engineers have developed different designs to suit varying driving conditions, performance goals, and terrain requirements. Let’s explore the most common types of differentials found in vehicles today.

Open Differential

The open differential is the simplest and most widely used type. It is cost-effective, reliable, and works well in most passenger cars. Under normal conditions, it provides smooth cornering by allowing each wheel to rotate independently.

However, the open differential has one major drawback: if one wheel loses traction, such as on ice, mud, or gravel, it can spin freely while the other wheel receives little or no power. This loss of traction can be problematic in slippery or uneven conditions, making the open differential less suitable for high-performance or off-road use.

Limited-Slip Differential (LSD)

The limited-slip differential, often abbreviated as LSD, is designed to overcome the shortcomings of the open differential. Under normal conditions, it behaves much like an open differential. However, when one wheel begins to slip, the LSD automatically applies resistance or torque biasing to maintain traction.

This makes LSDs especially valuable in performance cars and light off-road vehicles. They provide a balance between comfort, handling, and traction, ensuring that power is distributed more effectively even when road conditions are less than ideal. Modern LSDs can use clutch packs, helical gears, or viscous fluid to achieve this effect, depending on the design.

Spool Differential

A spool differential is not a true differential at all. Instead, it permanently connects both axle shafts so that the wheels always rotate together. This configuration is extremely effective for applications where traction is more important than handling, such as drag racing, rock crawling, or specialized off-road vehicles.

While spools provide maximum power delivery to both wheels, they make everyday driving impractical. Tight turns on pavement become uncomfortable and stressful on the drivetrain, which is why spools are generally reserved for competition and specialty builds.

Conclusion

At XJXPARTS, we provide a complete range of differential assemblies, ring and pinion sets, and installation kits for both retail and wholesale customers. Whether you need a single upgrade for a performance build or bulk supply for your shop, we’ve got you covered. Get in touch today to request a quote or place your order.