When discussing ring and pinion gears, you’ll often hear terms like two-cut, five-cut, face hobbed, and face milled. These refer to the ring and pinion manufacturing process and describe how the gears are machined. For anyone considering aftermarket upgrades or OE replacements, understanding these methods is essential to choosing the right gear set.

How Ring and Pinion Gears Are Made

The production of ring and pinion gears can be achieved through several machining methods. Among them, two processes dominate the industry:

- Face Milling (Five-Cut Process)

- Face Hobbing (Two-Cut Process)

Grinding can also be applied, but most aftermarket and OE gears are finished with a process called lapping to achieve precise tooth contact.

Face Milling The Five-Cut Gear Cutting Process

The five-cut method, also called face milling, is the traditional approach in the gear cutting process. Here, each gear tooth is shaped through multiple operations, requiring a total of five passes before lapping.

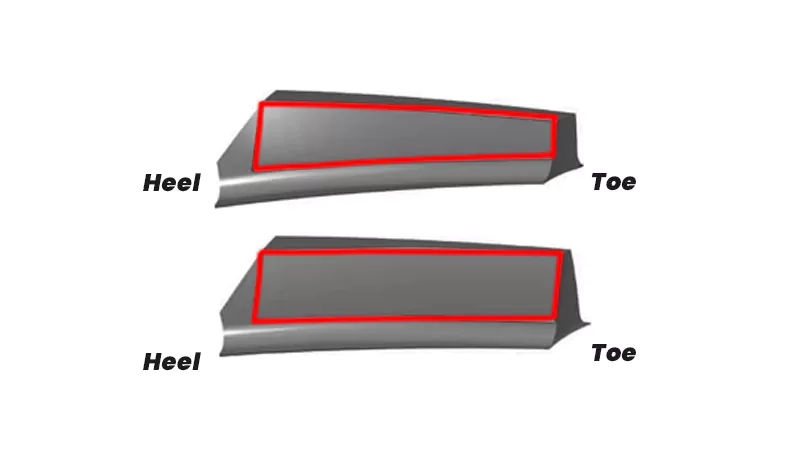

- Identification: In a face-milled ring gear, the heel (outer edge) of the tooth is taller than the toe (inner edge). This variable depth is a hallmark of the five-cut process.

- Benefits: Proven durability and reliability, widely used for decades in both OE and aftermarket applications.

This method is sometimes preferred by gear installers who are more familiar with the setup characteristics of face-milled gears.

Face Hobbing The Two-Cut Gear Cutting Process

The two-cut method, also known as face hobbing, is a more modern and efficient way to machine ring and pinions. With advanced equipment, each gear requires only one pass per side, reducing total machining passes from five to two.

- Identification: A face-hobbed gear has consistent tooth depth from heel to toe. When rolled with marking compound, the contact pattern often appears slightly slanted — a natural result of the bias condition in the hobbing process.

- Benefits: Faster production speeds, high precision, and consistency. Because of this efficiency, most OE manufacturers rely heavily on two-cut gears in large-scale production.

Face Milling vs Face Hobbing Gears

When comparing face milling vs face hobbing gears, the real difference lies in the gear cutting process rather than in end-use performance.

- Face Hobbed (2-Cut): Ideal for high-volume production, commonly used in OE gears, offers consistent quality at faster speeds.

- Face Milled (5-Cut): A traditional method that some installers prefer, especially in aftermarket applications where familiarity with setup and geometry is valuable.

Both methods produce strong, reliable gears when properly manufactured and installed. Your choice often depends on whether you are using OE replacement parts or aftermarket gear sets designed for off-road or performance use.

- Choose two-cut / face hobbed gears if you want modern OE-level precision and cost efficiency.

- Choose five-cut / face milled gears if you prefer a classic manufacturing process with a proven track record in specialized applications.

Conclusion

The production of ring and pinion gears has shifted from the traditional five-cut face milling process to the faster two-cut face hobbing method. Both deliver dependable results, but the difference between face hobbed and face milled gears lies mainly in the ring and pinion manufacturing process. By understanding these methods and how ring and pinion gears are made, you can make an informed choice for your vehicle — whether it’s for daily driving, towing, or hardcore off-road use.

We are a professional ring and pinion gear manufacturer, specializing in the production of high-precision differential gears. With advanced machining technology and strict quality control, our gears deliver superior strength, durability, and performance for both OE and aftermarket applications.

If you are looking for a reliable supplier of ring and pinion gears, contact us today to learn more about our manufacturing capabilities and customized solutions.