A differential is a crucial component in any vehicle, responsible for transmitting engine torque to the wheels. It splits power, allowing wheels to rotate at different speeds during cornering while delivering equal torque when traction is equal. By connecting the propeller shaft to the axle via a system of gears, a car differential ensures smooth and efficient power delivery.

Why Wheels Need to Rotate at Different Speeds

When a vehicle turns, the outer wheel travels a longer distance than the inner wheel. A differential allows each wheel to rotate independently, reducing tire wear and improving stability. Without a differential, one wheel would be forced to slide, increasing tire wear and decreasing control.

Key Components of a Differential

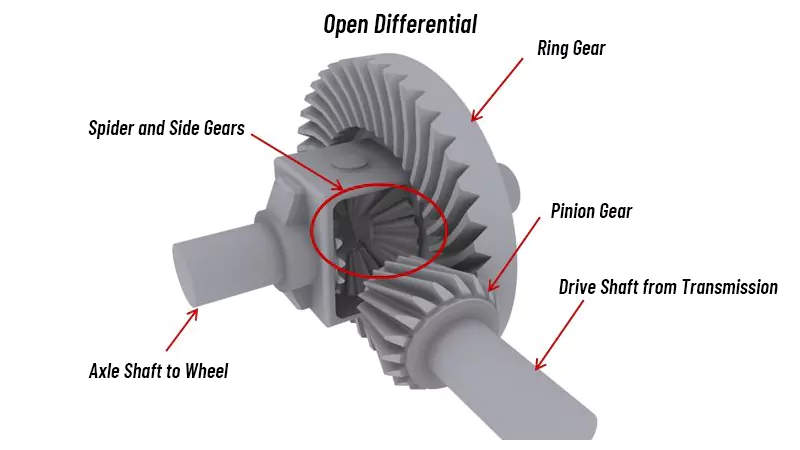

A differential consists of:

- Differential side gears (sun gears)

- Planet gears (spider gears)

- Ring gear (crown wheel)

- Pinion gear

- Drive shaft

- Axles or half shafts

The ring gear receives power from the pinion gear and drives the spider and sun gears, which transmit torque to the half shafts connected to the wheels. Spider gears allow each wheel to rotate at different speeds while maintaining balanced torque for smooth cornering.

How Differentials Work?

When driving straight, the sun gears, spider gears, and ring gear act as a single unit, and torque is evenly transmitted to both wheels. During turns, the spider gears rotate on their own axis as well as with the ring gear. This allows the outer wheel to rotate faster than the inner wheel while maintaining balanced torque, ensuring smooth cornering without tire wear.

Types of Differentials

Open Differential

An open differential allows wheels to rotate at different speeds. It works well on normal roads but may waste torque if one wheel loses traction on ice, snow, or sand. Open differentials are common in family sedans and economy cars due to simplicity and efficiency.

Limited Slip Differential (LSD)

A limited slip differential functions like an open differential under normal conditions but uses clutches and plates to prevent torque loss to a wheel with less traction. LSDs improve cornering performance and traction and are commonly used in performance cars, race vehicles, and off-road vehicles. They reduce tire wear compared to locking differentials.

Locking Differential

A locking differential sends full torque to both wheels regardless of traction differences. This provides maximum traction for off-road driving or rock climbing. However, it does not allow wheel speed differences, which may increase tire wear and drivetrain stress.

A Torsen differential uses worm gears to transfer torque efficiently without clutches or fluid resistance. Torsen differentials respond quickly to changing road conditions, require minimal maintenance, and behave like open differentials if a wheel loses contact with the ground. They are widely used in performance and all-wheel-drive vehicles.

Welded Differential (Spool Differential)

A welded differential, or spool differential, permanently locks both wheels together. It is often used in racing or drifting applications where constant wheel speed is desired. Welding can weaken components, making it unsuitable for standard road use.

Conclusion

Open differentials prioritize efficiency, limited slip differentials balance performance and traction, while locking or welded differentials maximize traction in extreme conditions. Advanced systems like torque vectoring differentials and Torsen differentials provide dynamic control for enhanced stability.

For professional differentials and drivetrain components, XJXPARTS offers high-quality solutions. Contact XJXPARTS to explore our full range of limited slip differentials, Torsen differentials, and other performance parts designed for your vehicle.