Before understanding the center differential lock, it is necessary to first grasp the principle of the center differential and its role in a four-wheel-drive system.

The function of a differential is to coordinate the speed differences between wheels caused by different travel paths during turning. Besides the speed differences between wheels on the same axle (left and right), there is also a difference between the front and rear wheels, which becomes especially significant when the vehicle is turning or driving on uneven terrain.

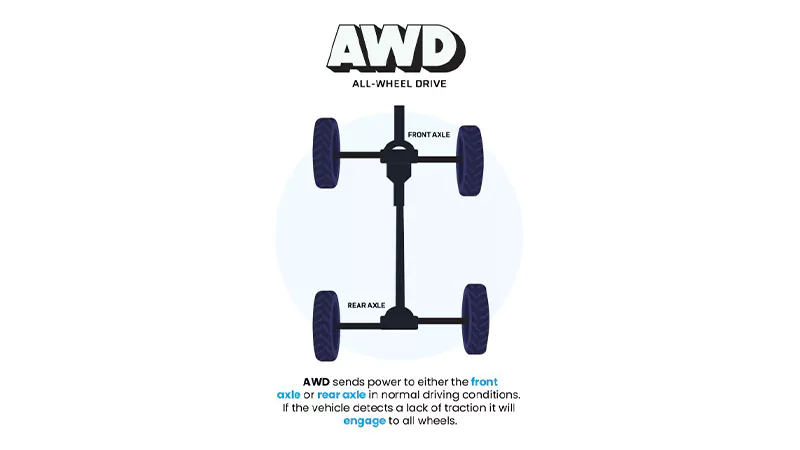

For full-time four-wheel-drive vehicles, since power is simultaneously sent to both the front and rear axles, lacking a center differential to distribute torque and coordinate rotational speeds will cause drivetrain binding, component wear, or even failure to drive properly. Therefore, a center differential must be incorporated into full-time 4WD systems to handle this task.

This article will focus on the working principle, practical function, and applicable scenarios of the center differential lock, helping readers deeply understand the logic behind this key off-road technology.

Why Is a Center Differential Needed?

During vehicle turning, the front and rear wheels follow different paths, meaning they need to rotate at different speeds over the same period. Just as left and right wheels require a differential, the speed difference between front and rear wheels also needs to be coordinated through a differential mechanism. This is the role of the center differential.

For front-wheel-drive or rear-wheel-drive vehicles, power is only distributed to one axle, while the other axle is free to rotate and is not driven. Therefore, a center differential is not required.

In full-time four-wheel-drive (All-Wheel Drive, AWD) systems, power is simultaneously sent to both front and rear axles. Because of this, a speed difference arises between the front and rear wheels during turning. Without coordination, excessive stress will be placed on the drivetrain, leading to damage. Hence, AWD systems typically feature a center differential.

The Function of the Center Differential Lock

The center differential lock’s function is to forcibly lock the rotational speeds of the front and rear axles to be the same when necessary—that is, it ensures the front and rear wheels receive an equal 50% power split.

Simply put, the center differential lock can temporarily “convert” a full-time AWD system into a mode similar to part-time 4WD’s high or low range, thereby enabling stronger off-road capability.

This function is mainly used on low-traction or unpaved surfaces, ensuring that even if one axle slips, the other axle still receives sufficient torque to help the vehicle escape.

When Should You Engage the Center Differential Lock?

The center differential lock should be used under off-road or unpaved road conditions, specifically including:

- Complex off-road terrain: Such as hills and depressions. When wheels on one axle lose traction, an unlocked center differential will send all power to the slipping wheels, causing the vehicle to lose forward momentum. Engaging the center differential lock forces equal power distribution to front and rear axles, so even if some wheels slip, the other axle can still provide drive.

- Reversing out of being stuck: For example, if the front wheels are stuck in mud, and the center differential is unlocked, the front wheels will continue to spin uselessly, with no power sent to the rear wheels. Engaging the center differential lock and selecting reverse gear allows the rear wheels to provide power and help free the vehicle.

- Climbing steep slopes: When climbing, the vehicle’s weight shifts backward, reducing front wheel traction. If the front wheels slip and the center differential is not locked, the rear wheels cannot effectively receive torque. Engaging the center differential lock ensures the rear wheels receive a stable 50% power, improving climbing ability.

Impact on Turning Radius

The center differential lock should not be used on paved or high-traction surfaces. On asphalt roads, tires have strong grip, and speed differences between wheels cannot naturally release. Forcing the lock creates internal stress in the drivetrain, potentially damaging gears and components.

Alternative - Traction Control Systems

Many modern full-time AWD vehicles do not have a traditional mechanical center differential lock, but instead use electronic traction control systems to achieve a similar effect.

The traction control system, through an electronic control unit, intelligently distributes power based on tire grip conditions, mimicking the center differential lock’s function for off-road recovery.

When a wheel loses traction, the system applies braking force to that wheel and transfers more torque to wheels with grip, helping the vehicle traverse difficult terrain.

Limitations of the Center Differential Lock

Imagine a 4WD vehicle driving on an axle-crossing terrain, with the left front and right rear wheels suspended off the ground. Even if the center differential lock is engaged, front and rear axles still get 50% power each. However, since each axle has a slipping wheel in the air, all power will be sent to these non-contact wheels, preventing vehicle recovery.

At this point, relying solely on the center differential lock is insufficient. If the vehicle has front and rear axle differential locks, those should be engaged immediately to ensure wheels with traction receive power and enable recovery.

Conclusion

The center differential and its locking function are critical components of full-time AWD systems. When used correctly, they greatly enhance vehicle off-road capability and recovery ability.

However, the center differential lock is not a universal solution; it should only be engaged under specific conditions to avoid mechanical damage. In combination with traction control and front/rear differential locks, it allows the full potential of a four-wheel-drive system to be realized.