In differential setup and axle assembly, the ring and pinion contact pattern is one of the most vital indicators of correct gear alignment. For technicians and engineers, being able to read and adjust these patterns accurately is critical to achieving quiet operation, minimizing wear, and maximizing drivetrain longevity.

Characteristics of an Ideal Pattern

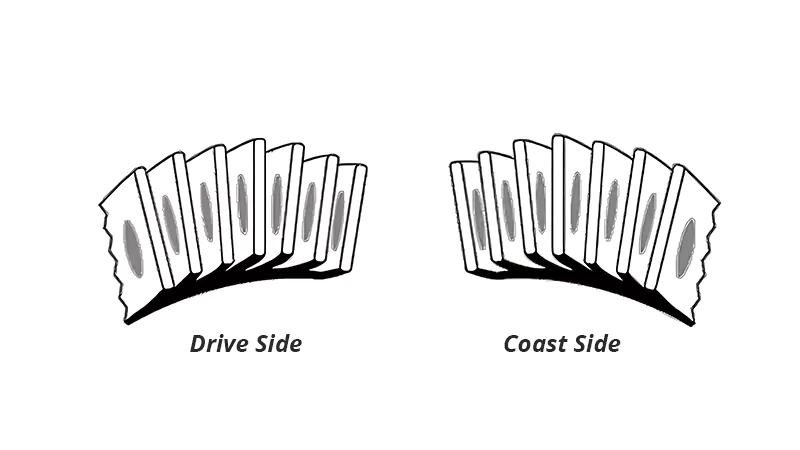

A good contact pattern is characterized by an oval-shaped mark that sits centered between the face (outer top) and flank (inner bottom) of the tooth. On the drive side, the contact should appear slightly biased toward the toe (the inner edge of the gear tooth) but remain well centered. On the coast side, a slightly heel-biased pattern is acceptable, although it should also stay centered vertically. This pattern indicates optimal load distribution and proper pinion depth.

Below is an example of a textbook gear pattern:

What Causes a Poor Pattern?

When the pinion depth or backlash is incorrectly set, the contact pattern will shift away from the ideal zone. If the pattern is too close to the face of the tooth, this indicates that the pinion is too shallow and needs to be moved deeper using thicker pinion shims. Conversely, a pattern near the root means the pinion is set too deep and should be shimmed outward.

A pattern heavily biased toward the toe suggests excessive backlash. In contrast, if the pattern is near the heel, the backlash is too tight. These shifts can occur on both the drive and coast sides, and they compromise the gearset’s ability to handle torque smoothly, potentially leading to noise or failure.

How to Evaluate the Pattern?

To inspect the contact pattern, apply gear marking compound evenly across several ring gear teeth. Rotate the ring gear with resistance applied (such as a pry bar with drag) to simulate loaded conditions. Avoid free-spinning the gears, as this produces misleading diagonal streaks instead of true load contact.

Technicians should inspect patterns on both drive and coast flanks. However, in most applications—particularly performance and off-road—the drive side pattern takes priority during adjustment. Coast side patterns are secondary, unless the vehicle operates in significant reverse torque conditions.

Adjustment Process

Pinion depth should always be adjusted before backlash. Starting with an approximate shim thickness, adjust the pinion depth until the pattern becomes vertically centered between the face and root of the tooth. Once this is achieved, backlash can be fine-tuned by adjusting the carrier bearing preload or shim pack. Shifting the ring gear closer to the pinion reduces backlash, while moving it away increases it.

Proper setup requires a methodical approach. Inspect the pattern on at least three adjacent teeth to account for gear runout. After each adjustment, re-mark and re-check to ensure consistent contact and no edge-loading.

The contact pattern should be repeatable across several revolutions. If it changes position from tooth to tooth, this could indicate gear runout, misalignment, or improper preload. An inconsistent pattern is a red flag that should never be ignored, especially in high-performance or off-road applications where drivetrain reliability is critical.

Conclusion

A good ring and pinion pattern is more than just a diagnostic—it is visual proof that the gearset is properly aligned, correctly loaded, and ready for real-world torque. For skilled technicians and engineers, understanding how to read and adjust this pattern is an essential skill. Through careful adjustment of pinion depth and backlash, and precise evaluation of the contact area under load, optimal performance and long-term durability can be achieved.