Picture this: You’re merging onto the interstate when an eerie metallic howl rises from your truck’s undercarriage. That haunting sound isn’t ghost stories – it’s your differential begging for attention.

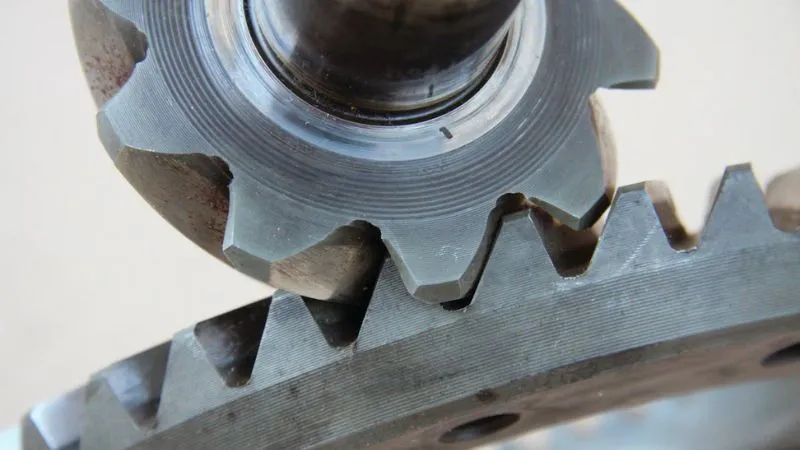

Ring and pinion gears work tirelessly to transfer engine power to your wheels. But when these precision components wear out, they can trigger a chain reaction of drivetrain failures. Let’s decode the red flags mechanics wish every driver knew.

1.Whining and Howling: Signs of a Failing Differential

Symptoms

A high-pitched whining or howling noise, especially during acceleration or deceleration. The sound may become more pronounced when the vehicle is under load or when coasting at certain speeds. In some cases, the noise may be intermittent at first but gradually worsen over time.

Cause:

- Improper Gear Meshing: Misalignment or incorrect gear settings can lead to abnormal sounds.

- Worn Gear Teeth: Over time, wear on the teeth can cause noise during operation.

- Incorrect Backlash Settings: If the backlash is not within the recommended range, it can lead to improper gear engagement and noise.

- Insufficient Lubrication: Lack of adequate gear oil or degraded oil increases friction, causing noise and wear.

- Worn Bearings: Bearings that support the gears may wear out, leading to misalignment and increased noise levels.

Solution:

- Adjust Gear Backlash: If caught early, adjusting the backlash or replacing worn bearings can reduce noise.

- Proper Lubrication: Ensure the differential has the correct type and amount of gear oil to reduce friction and noise.

- Replace Worn Gears: If noise persists despite adjustments, the ring and pinion gears may be excessively worn and need replacement.

- Regular Inspections: Regular maintenance and timely inspections help catch early warning signs and prevent severe issues from developing.

2. Drivetrain Vibrations: Causes and Fixes

Symptoms

Noticeable vibrations in the drivetrain, especially during acceleration or deceleration, which may be felt through the steering wheel, floorboard, or seats. In extreme cases, the vehicle may shake, especially when turning or under load. These vibrations may start mild but worsen over time, affecting vehicle comfort and safety.

Cause:

- Misaligned Gears: When gears aren’t aligned properly, it disrupts torque transfer, causing vibrations or shaking, especially under load.

- Worn Bearings: Damaged or worn bearings can misalign gears, leading to vibrations in the drivetrain.

- Uneven Gear Wear: Excessively worn ring and pinion teeth can cause poor meshing, resulting in vibrations.

- Excessive Backlash: A large gap between gear teeth (backlash) can lead to improper meshing and increased vibrations.

- Failing Differential: A faulty differential may cause uneven power distribution, worsening vibrations and instability.

Solution:

- Inspect Gear Alignment: Check if the ring and pinion gears mesh properly and verify if the backlash is within specifications.

- Check Bearings: Look for wear or noise in the bearings. Replace if necessary.

- Lubrication: Ensure the correct gear oil is used to reduce friction and prevent further vibrations.

- Replace Gear Set: If misalignment, wear, or a failing differential is found, consider replacing the entire ring and pinion gear set.

- Differential Replacement: If the differential is causing issues, replace it along with the gears to prevent recurring problems.

3.Differential Fluid Leaks: The Hidden Danger

Symptoms

Puddles of gear oil under the differential or visible leaks from the housing are the most common signs. You might also notice a decrease in fluid levels in the differential over time. If the leak is significant, the smell of burning oil might be present, and you may experience strange noises or overheating in the drivetrain. If left unchecked, these leaks can lead to severe gear damage and even complete failure of the differential.

Cause:

- Worn Seals: Over time, the seals that help keep the gear oil contained can deteriorate, leading to leaks.

- Damaged Gaskets: The gaskets between the differential housing and cover may crack or wear out, allowing oil to escape.

- Cracks in the Housing: Cracks or other structural damage to the differential housing can cause oil to leak out, compromising the lubrication system.

- Overheating: Excessive heat can break down seals and gaskets, making them more prone to leaking.

- Improper Installation: Poor installation of seals or gaskets during maintenance can result in fluid leaks over time.

Solution:

- Regularly Check for Leaks: Inspect the differential regularly for any signs of oil leaks, especially around the seals, gaskets, and housing.

- Ensure Proper Sealing: If leaks are detected, check that the differential is properly sealed. Replace worn or damaged seals and gaskets as needed.

- Inspect the Housing: Check the differential housing for any cracks or damage that could lead to fluid leakage. If cracks are found, the differential housing may need to be replaced.

- Top Up Fluid Levels: If fluid levels are low, top up the gear oil to prevent damage due to insufficient lubrication. Always use the recommended type of gear oil.

- Timely Replacement: If the differential has experienced significant fluid loss or if the gears show signs of wear, it may be necessary to replace the ring and pinion gear set to prevent further damage.

4. Uneven Tire Wear: Is Your Differential to Blame?

Symptoms

Uneven tire wear is a key sign of a failing differential or worn ring and pinion gears. One side of the tire may wear faster, particularly on the edges. Difficulty turning or a “pulling” sensation can indicate uneven torque distribution, leading to traction loss, especially when accelerating or cornering.

Cause:

- Failing Differential: A malfunctioning differential can unevenly distribute torque, leading to inconsistent traction and abnormal tire wear.

- Worn Ring and Pinion Gears: Excessively worn or misaligned gears can cause improper meshing, disrupting power transfer and causing uneven tire wear.

- Improper Gear Backlash: Incorrect gear backlash leads to improper meshing, causing inconsistent power transfer and uneven wear.

- Damaged Bearings: Worn bearings can cause misalignment, disrupting gear meshing and leading to uneven power distribution and tire wear.

Solution:

- Inspect the Differential: If uneven tire wear occurs, have a professional check for signs of component failure, such as worn bearings or damaged gears.

- Check Ring and Pinion Gears: Look for excessive wear or misalignment. Replacing worn or misaligned gears ensures proper function and power distribution.

- Adjust Gear Backlash: Correcting improper backlash improves gear meshing and torque distribution, reducing uneven wear.

- Replace Worn Bearings: Replace worn bearings to maintain proper gear alignment and prevent further damage.

- Regular Maintenance: Regular inspections can catch issues early, preventing costly repairs and maintaining optimal performance.

5. Metal Debris in Gear Oil: Warning Signs of Gear Damage

Symptoms

Metal shavings or a metallic sheen in the differential oil indicate internal gear damage, often accompanied by a burnt smell from overheating. Performance may decline with rough power delivery or unusual noises. If ignored, the metal debris will degrade the oil, accelerating wear and potentially causing gear failure.

Cause:

- Excessive Friction: Worn gears generate metal particles that contaminate the oil, increasing wear and metal shavings.

- Improper Gear Alignment: Misalignment causes uneven gear contact, creating friction that produces metal particles.

- Insufficient Lubrication: Low or degraded oil leads to friction, accelerating wear and metal debris formation.

- Overheating: High temperatures degrade oil, reducing lubrication and increasing wear, leading to metal particles.

- Damaged Bearings or Seals: Worn bearings or seals cause misalignment, creating excess wear and contaminating the oil with metal debris.

Solution:

- Regularly Change Gear Oil: Change the oil as per manufacturer recommendations to maintain proper lubrication and reduce friction.

- Inspect for Metal Debris: After oil changes, check for metal particles, indicating internal gear damage.

- Check Gear Alignment: Misalignment causes increased wear. Adjust alignment or replace gears if necessary.

- Replace Worn Gears: If metal debris is found and gears are damaged, replace them immediately to prevent further issues.

- Inspect Bearings and Seals: Check and replace worn bearings and seals to maintain proper alignment and prevent friction.

- Avoid Overheating: Ensure proper lubrication and operating temperatures to prevent overheating and additional wear.

Conclusion:

Maintaining your differential system is crucial for ensuring the longevity and performance of your vehicle. By addressing common issues such as vibrations, abnormal noises, fluid leaks, uneven wear, and metal debris, you can prevent costly repairs and keep your drivetrain running smoothly. Regular inspections and timely maintenance are key to detecting problems early and avoiding severe damage. If you notice any of the symptoms mentioned, don’t hesitate to consult a professional to inspect and repair your differential. Taking proactive steps today will ensure the reliability of your vehicle for years to come.

If you need high-quality ring and pinion gears, feel free to contact XJX Auto Parts. As a factory, we specialize in providing premium differential gears and offer expert guidance from our professional team to help you choose the right parts for your vehicle.