What Exactly Are Ring and Pinion Gears?

The assembly consists of two gears:

- The pinion gear, which is driven by the driveshaft.

- The ring gear, a larger gear mounted to the differential carrier.

Why Ring and Pinion Gears Are So Important in Drivetrain Design

- Torque multiplication: They increase the torque delivered to the wheels.

- Load handling: They absorb the stress created by engine power and vehicle weight.

- Final drive determination: They establish the vehicle’s final drive ratio.

- Compatibility with differential types: They work with open, limited-slip, locking, and torque-biasing differentials.

- Influence on NVH: Gear design affects noise, vibration, and harshness characteristics.

How Ring and Pinion Gears Work Inside a Differential

1. Power Transfer from the Driveshaft to the Pinion Gear

Engine torque travels through the transmission and down the driveshaft. The driveshaft connects directly to the pinion gear via a flange or yoke. As the driveshaft spins, the pinion turns at the same speed.

2. The Pinion Gear Drives the Ring Gear

The angled teeth on the pinion mesh with the matching teeth on the ring gear. This hypoid geometry enables smooth contact and quieter operation than straight-cut gear profiles. Because the pinion is typically offset from the ring gear’s centerline, it results in greater tooth surface engagement.

3. Rotation Reaches the Differential Carrier

When the pinion spins the ring gear, the entire carrier assembly rotates. Depending on the type of differential—open, LSD, or locker—the carrier then distributes torque to the axle shafts.

4. Torque Travels to the Wheels

Finally, the motion transfers from the axle shafts to the wheels, moving the vehicle forward.

This mechanical sequence makes ring and pinion gears critical not only for power transmission but also for overall drivability.

The Dramatic Role of Gear Ratios in Ring and Pinion Gears

- A 3.73 ratio means the pinion turns 3.73 times for each rotation of the ring gear.

- A 4.56 ratio means the pinion turns 4.56 times for each rotation.

- Performance upgrades

- Off-road builds

- Heavy-duty towing setups

- Racing, drifting, and track cars

- Commercial load-bearing vehicles

Key Materials and Manufacturing Processes Behind Ring and Pinion Gears

Lorem ipsumHigh-quality ring and pinion gears must endure extreme loads, rapid rotation, and constant heat cycles. As a result, their manufacturing process involves advanced materials and precision engineering. dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

1. High-Strength Alloy Steel

- 8620 steel

- 4320 steel

- Special proprietary hypoid alloys

2. Advanced Forging and Machining

Processes often include:

- Forging for structural integrity

- Multi-axis CNC machining

- Precision lapping

- Tooth hardening and heat treatment

Proper machining ensures optimal gear tooth geometry, while heat treatment improves surface hardness and durability.

3. Matched Gearset Production

Ring and pinion gears are always sold in matched sets. This is because they are lapped together during manufacturing to create perfect tooth engagement. Mixing unmatched gears would lead to severe noise, heat generation, and premature failure.

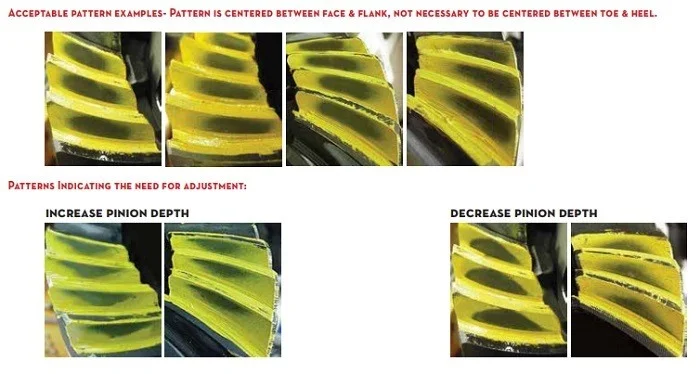

Understanding Gear Tooth Contact Pattern in Ring and Pinion Gears

One of the most critical aspects of evaluating ring and pinion gears is examining the contact pattern. This pattern shows how the gears mesh under load. Proper patterns ensure quiet operation, long life, and efficient torque delivery.

Technicians check patterns using marking compound during setup. A correct pattern will appear centered on the tooth, with balanced drive and coast patterns.

- Incorrect pinion depth

- Improper backlash

- Faulty shimming

- Worn bearings

- Damaged gear teeth

High-Impact Factors

For buyers, mechanics, and distributors, understanding what influences performance is vital. Below are the most significant factors affecting ring and pinion gears in operational environments.

1. Precision in Tooth Geometry

Small deviations in machining affect noise levels, heat, and torque transfer. Superior gears maintain highly consistent tooth profiles.

2. Proper Heat Treatment

Inadequate heat treatment can cause premature wear or tooth chipping under load. High-performance gears require deep, uniform hardening.

3. Material Quality and Purity

Impurities reduce fatigue strength and durability. Premium manufacturers use controlled-quality alloy sources.

4. Accuracy During Installation

Incorrect setup is one of the most common causes of failure. Even high-quality ring and pinion gears will fail prematurely if:

- Backlash is incorrect

- Preload is set improperly

- Pinion depth is misaligned

Professional installation extends lifespan and reduces warranty issues.

5. Break-In Procedure

After installation, gears require a careful break-in cycle. This helps stabilize heat and ensures the surface hardening remains intact.

Where Ring and Pinion Gears Are Commonly Used

- Automotive passenger vehicles

- Commercial trucks and vans

- High-performance sports cars

- Track and drag racing vehicles

- Off-road 4×4 and rock crawlers

- Agricultural machinery

- Specialty industrial equipment

Wherever torque must be delivered efficiently, ring and pinion gears play a central role.

How to Identify High-Quality Ring and Pinion Gears

- Smooth and consistent tooth finish

- Matched precision lapping

- Accurate ratio labeling

- Traceable manufacturing codes

- Low-noise engineering

- High-strength alloy composition

- Strict heat treatment control

Reputable manufacturers also provide detailed inspection reports and quality documentation.

Conclusion

Ring and pinion gears remain one of the most influential parts of any driveline system. Their role in torque delivery, load management, and overall vehicle performance makes them indispensable for manufacturers, service professionals, and vehicle builders. Understanding how they function, how they are made, and how to evaluate their quality allows both B2B and B2C buyers to make informed decisions.

From material selection to precision machining and professional installation, every step contributes to the reliability and lifespan of ring and pinion gears. Whether the application is high-performance racing, heavy towing, or daily driving, choosing the right gearset ensures stronger, smoother, and more efficient power transfer.

At XJX Parts, we manufacture high-quality ring and pinion gears with strict material control, advanced machining, and consistent performance standards. As a factory-level supplier, we offer competitive pricing, stable lead times, and reliable product consistency. Customized solutions are also available; we can produce ring and pinion gears according to your specific technical requirements, ratios, materials, or application needs. If you are looking for a dependable supplier or exploring custom development, you are welcome to contact us at any time.