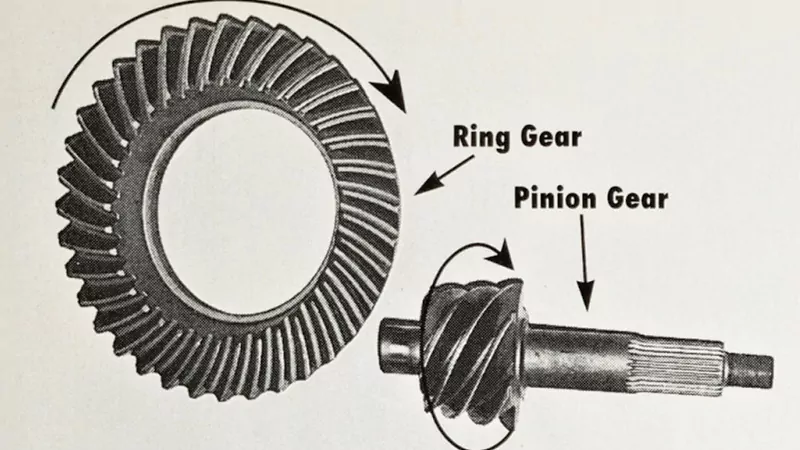

When people first learn about differential gear sets, a common question appears almost immediately: “If we want a higher gear ratio, why not simply add more teeth to the ring gear without increasing its diameter?”

It sounds reasonable at first glance. In theory, more teeth on the crown wheel could increase the ratio without redesigning the housing. But the reality of gear engineering is far more nuanced. Once you understand how tooth size, load capacity, and pinion geometry work together, the answer becomes clear, and surprisingly logical.

Gear Ratio Isn’t Just About Tooth Count

The basic formula is simple:

Ring Gear Teeth ÷ Pinion Teeth = Gear Ratio

So yes, adding teeth to the ring gear could increase the ratio. But in real-world differential design, tooth count is tied to another critical factor:

The gear’s module (the size and thickness of each tooth).

You can’t freely shrink tooth size to squeeze in more teeth. If the ring gear keeps the same diameter but gains additional teeth, the only way to make that possible is:

- the teeth become thinner

- the base circle shrinks

- and the overall tooth strength drops sharply

In a differential that handles high torque, especially in trucks, SUVs, or performance cars — that is unacceptable. Thin teeth simply cannot survive the load.

Higher Gear Ratios Mean Higher Torque Loads

A “higher numerical gear ratio” (like 4.56, 4.88, 5.29) multiplies torque at the wheels. That means:

- the ring gear is exposed to much higher reaction torque

- heat and contact stress increase

- the pinion experiences a more aggressive mesh angle

If the ring gear diameter stays small while loads go up, tooth root stress rises dramatically.

This is why manufacturers increase not just tooth count, but the physical size of the crown wheel and pinion to absorb this extra punishment.

A larger ring gear means:

- deeper, stronger teeth

- more robust tooth roots

- a wider contact pattern

- better heat distribution

- longer life under high torque

This is especially obvious when comparing a 4.10 ratio in a mid-size pickup versus a 5.29 ratio used in heavy off-road builds — the housings and gears are simply not the same size.

The Pinion Gear Also Limits What You Can Do

Another practical constraint is the minimum number of teeth on the pinion. If the ring gear gets more teeth but the pinion tooth count stays the same, the ratio increases. But if the ratio becomes very high, engineers normally reduce pinion tooth count as well.

The problem:

- A pinion with too few teeth becomes noisy.

- Undercutting occurs at low tooth counts.

- Contact strength plummets.

- Durability drops.

So to keep the pinion within a healthy, manufacturable range (usually 8–12 teeth), the entire gear set size must increase. Try squeezing a 6-tooth pinion into a standard axle housing — it becomes a recipe for gear howl and early failure.

Conclusion

If you’re tuning, modifying, or upgrading a vehicle, whether it’s a performance car or a 4×4, understanding this helps explain why:

- Certain high-ratio gears require a different axle housing

- Some OEMs use larger differentials in diesel or towing models

- High-strength aftermarket gear sets cost more

- Ring gear diameter is a key factor in torque capacity

Gear ratio changes are more than a number on paper, they are a real mechanical challenge that affects the entire differential assembly.

If your business requires consistent quality, engineering guidance, or large-volume supply of ring gear and pinion gear, XJXPARTS provides the expertise and production capacity to meet your requirements.