1. Diagnosing Gear Noise

- Whine on Acceleration: This is typically caused by the pinion gear being too deep or too shallow in relation to the ring gear. When the gears are under load, the contact point shifts to a non-optimized area of the tooth.

- Whine on Coast (Deceleration): If the noise appears only when you let off the gas, it often points to a problem with the pinion bearing preload or a shift in the backlash that occurs when the gears are loaded on the “coast” side of the teeth.

- Rhythmic Clunking: A steady “click” or “clunk” that increases with vehicle speed usually indicates a chipped or broken tooth.

2. Improper Backlash and Gear Alignment

Proper alignment is verified using a gear marking compound. A pattern that is too high (at the face) or too low (at the flank) concentrates all the mechanical stress on a small portion of the tooth, leading to rapid deformation and noise.

3. The Role of the Carburized Case and Surface Hardness

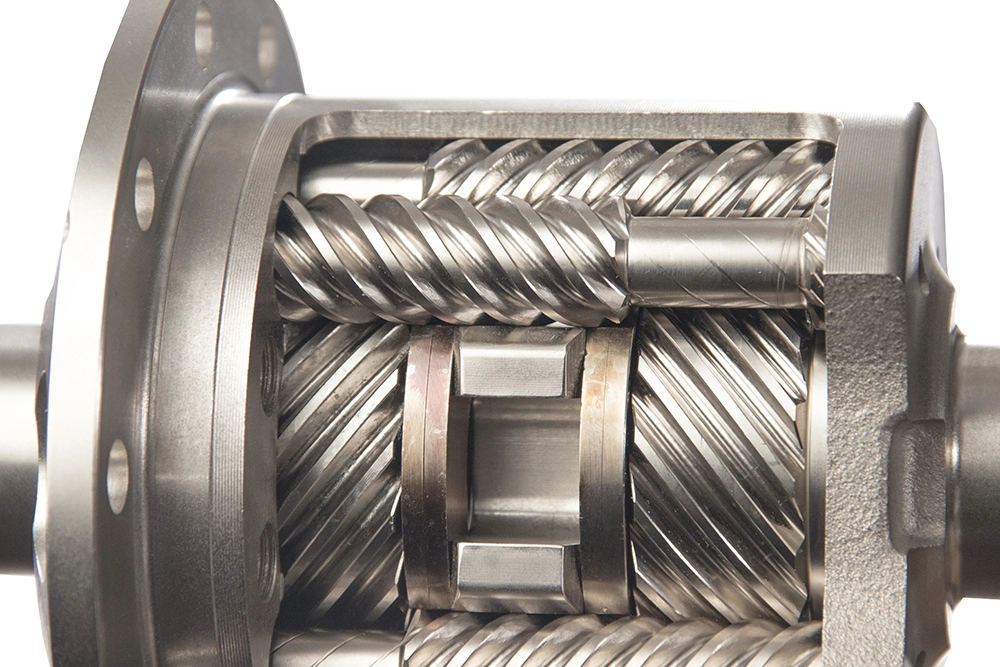

The carburized case is the carbon-enriched outer shell of the gear tooth. Its job is to provide the extreme hardness required to resist the sliding friction inherent in hypoid gears.

- If the case is too thin: The surface may lack the structural integrity to support heavy loads, leading to “sub-surface deformation” where the hard shell collapses into the softer core. This creates surface roughness and loud whining.

- If the case is too thick, the gear tooth can become overly brittle. While it may be very quiet initially, it loses the ability to absorb shock, making it prone to snapping under sudden torque.

4. Lubrication Failure and Thermal Distress

5. Fatigue, Pitting, and Spalling

6. Distinguishing Gear Noise from Bearing Noise

It is a common mistake to replace a ring and pinion set when the actual culprit is a carrier or pinion bearing.

- Pinion Bearing Noise: Usually a high-frequency whirring sound. Since the pinion rotates several times for every one rotation of the ring gear, the sound is much faster than a ring gear “click.”

- Carrier Bearing Noise: A lower-pitched growl that may change in intensity when the vehicle is steered side-to-side (as the load shifts from one bearing to the other).

Conclusion

At XJXPARTS, we are a specialized factory committed to producing high-precision drivetrain components. Our ring and pinion sets are manufactured with strict metallurgical controls to ensure durability and silent operation. If you are looking for reliable gear sets or need a professional manufacturing partner, please contact us today for more information.