Upgrading to a set of massive, aggressive tires is often the first modification off-road enthusiasts and truck owners make. It instantly transforms the vehicle’s aesthetic and increases ground clearance for rugged terrain. However, shortly after leaving the tire shop, many drivers notice a frustrating change: the vehicle feels sluggish, the transmission hunts for gears, and fuel economy plummets.

This performance dip occurs because changing the tire diameter without adjusting the internal gearing disrupts the mechanical harmony of the drivetrain. To restore that lost power, you must address the heart of the differential: the crown pinion set. Understanding the relationship between tire size and gear ratios is essential for anyone looking to maintain vehicle longevity and performance.

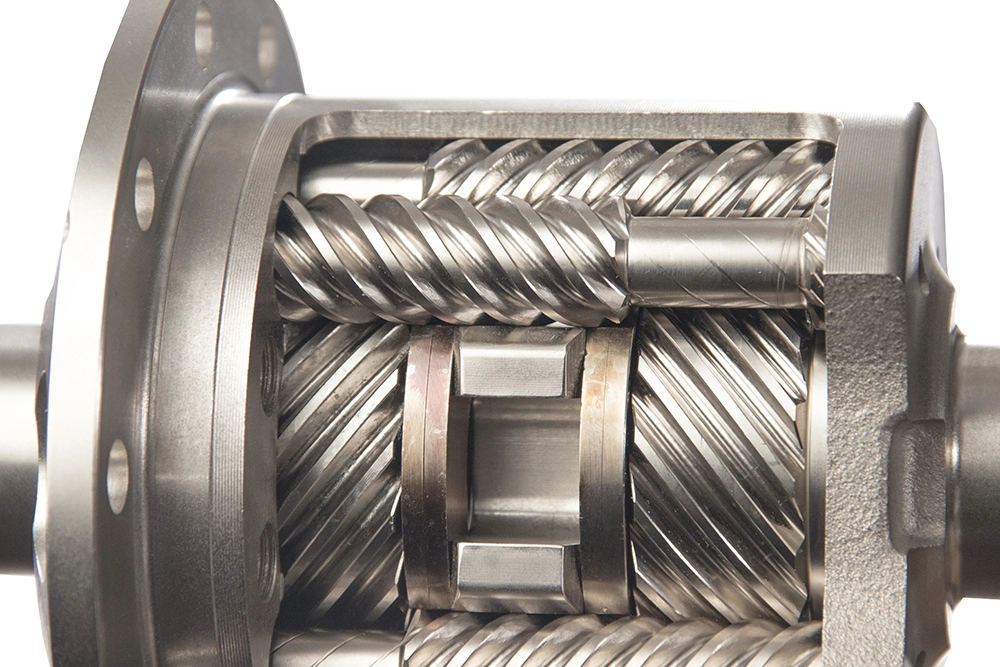

To understand why a new crown pinion set becomes necessary, we must look at the basic physics of how a vehicle moves. Your engine produces torque, which is transmitted through the transmission and driveshaft to the pinion gear. The pinion gear then turns the crown wheel (also known as the ring gear), which ultimately spins the axles and tires.

When a vehicle leaves the factory, engineers have carefully selected a crown pinion set ratio that balances acceleration, towing capacity, and fuel economy based on the stock tire height. For instance, if your truck came with 30-inch tires and a 3.73 gear ratio, the engine operates within an optimal RPM range at highway speeds.

Many drivers attempt to live with the power loss, unaware that they are causing long-term damage to their vehicle. If you have recently upgraded your tires, watch for these specific symptoms that indicate your factory crown pinion set is no longer adequate:

Selecting the right ratio is not about finding the “biggest” number; it is about returning the engine to its factory-designed RPM range. To find the exact mathematical match for your new tire setup, you can use the following industry-standard formula:

For example, if you are moving from a 31-inch stock tire to a 37-inch tire with a 3.55 base ratio, the calculation would be: (37 / 31) × 3.55 = 4.23. In this case, a 4.27 or 4.56 gear set would be the most appropriate choice to restore your vehicle’s factory performance and fuel economy.

Not all crown pinion sets are created equal. Because these components are subjected to immense pressure and heat, the manufacturing process is critical. When sourcing gears for a professional repair shop or a personal project, paying attention to the technical specifications is vital for durability.

Most high-quality aftermarket gears are forged from 8620 or 20CrMnTi alloy steel. These materials offer an excellent balance of surface hardness and core toughness. After the gears are cut, they undergo a process called carburizing (heat treatment), which hardens the outer “skin” of the teeth to resist wear while keeping the inner core flexible enough to absorb shock loads without snapping.

Furthermore, premium sets undergo a process known as “lapping.” This involves running the crown and pinion together with an abrasive compound to ensure the teeth mesh perfectly. A lapped crown pinion set runs cooler and significantly quieter, eliminating the annoying “whining” noise often associated with cheaper, inferior gears.

Replacing a crown pinion set is perhaps the most meticulous task in automotive maintenance. Unlike a bolt-on exhaust or an air intake, gears require precision measurements down to the thousandth of an inch.

This determines how deep the pinion gear sits in relation to the center of the crown wheel. Improper depth leads to a weak contact pattern and eventual tooth failure.

This is the small amount of “play” between the teeth. Too little backlash causes the gears to bind and overheat; too much causes clunking and shock-load damage.

This refers to the tension placed on the bearings. Correct preload ensures the gears stay aligned even under heavy torque loads.

A professional installer will use a marking compound to check the “tooth contact pattern.” By looking at where the gears touch, they can determine if the shims need to be adjusted. For a B2B buyer or a fleet manager, ensuring that your mechanics have access to high-precision crown pinion sets with consistent tolerances is the best way to reduce costly warranty claims and “comebacks.”

Once a new crown pinion set is installed, the work isn’t quite finished. New gears require a “break-in” period. During the first few hundred miles, the gears are literally polishing each other. It is standard practice to drive the vehicle for short distances (15-20 miles), allowing the differential to cool completely between trips.

After the initial 500 miles, the differential fluid should be changed. This removes any microscopic metal particles shed during the break-in process. Using a high-quality synthetic gear oil with the correct viscosity ensures that the friction surfaces remain protected for hundreds of thousands of miles.

For those in the automotive trade, providing customers with a reliable crown pinion set is about more than just a sale; it is about reputation. In the world of international trade, sourcing from a manufacturer that understands the nuances of metallurgy and precision machining is the difference between a satisfied repeat customer and a logistical nightmare of returns.

Whether you are a workshop owner helping a client fix a noisy differential or a distributor supplying the off-road community, the demand for high-performance gear sets continues to grow as trucks and SUVs dominate the global market. By choosing components that meet or exceed OEM standards, you ensure that the vehicle remains safe, efficient, and powerful, regardless of the tire size.